Humanoid robots accelerate at lightning speed, even faster than I thought.

The development curve went vertical. They are not science fiction anymore. They’re the next major tech revolution about to happen, and it could be as big as the Industrial Revolution.

Over the past year, progress in humanoid robotics has accelerated faster than almost anyone expected. Figure, Tesla, and Neura Robotics have turned them into functioning prototypes that can already perform basic and advanced human tasks. A China produces them at low costs.

If the current pace continues, humanoid robots will soon be part of everyday life.

Within the next 5 years.

How Robots Learn

Until recently, building humanoid robots was incredibly difficult.

Every movement had to be programmed manually, line by line, to handle every possible situation. It was slow, expensive, and far too rigid for the real world.

They basically fell down every step of the way.

Then AI entered the picture.

Instead of relying on pre-written code, robots can now learn by training in simulated environments. They can practice for thousands of hours in a digital space (learning how to walk, balance, and manipulate objects) all within minutes of real time.

Add to that the rapid advances in motor design, battery capacity, and computing power, and we suddenly have machines that move, perceive, and adapt in ways that were unthinkable just a few years ago.

The Latest Generations

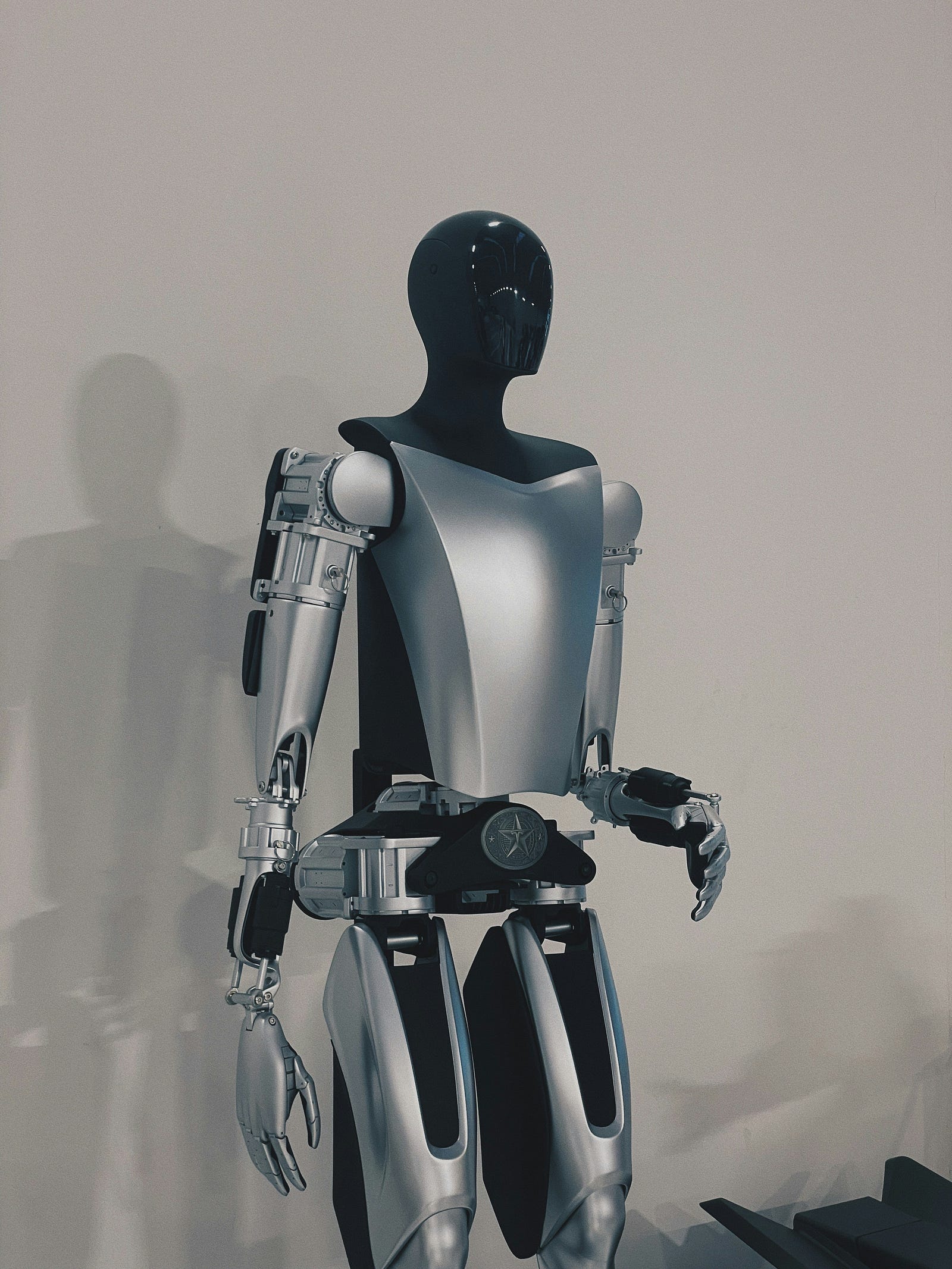

The most recent example is the Figure 3, which looks and moves very human.

It can pick up fragile objects, recognize clutter, sort laundry, and carry trays or serve drinks. It’s designed to operate in a real-world environment, not controlled lab settings.

Tesla Optimus is following a similar path. The company claims it could produce up to a million units within the next few years. But Tesla claims a lot… and rarely accomplishes.

Nonetheless, the robot has made visible progress (walking smoothly, manipulating delicate items, and performing repetitive industrial tasks with precision).

In Germany, Neura Robotics has developed its own humanoid system, designed more for domestic and collaborative environments. Their robots integrate visual and auditory AI to recognize people, understand voice commands, and perform small physical tasks.

What unites these projects is intelligence.

It looks like a scene from iRobot.

These robots don’t need to be micromanaged, they can analyze, decide, and adapt on their own.

And that’s crazy technology… and quite a bit scary.

Become a Superwriter

With THE best writing system for Notion, tailored towards Substack newsletters, Medium stories, blog posts, social media posts, and other aspects of a writing business like finances, sponsors and affiliates, goals, and more.

What This Means for Work

We all know the obvious implications:

- Robots could take many, maaany jobs from humans, just like every major technological revolution did

- Robots can make basic tasks at home, at work, and, most importantly, in factories, way faster and more automated

But there are other implications that are mentioned less often.

Humanoid robots could transform how and where we produce goods.

For decades, manufacturing has been outsourced to countries with lower labor costs. Which means cheap work, bad conditions, and often inferior products produced in Asia or Third World countries around the globe, just to be shipped back to us.

Robots will dramatically change that!

Robots don’t have salaries, health insurance, or vacation time. They can work around the clock, follow instructions precisely, and operate in environments built for humans, meaning they could take over existing factories without redesigning them from scratch. Or they work in confined, dark spaces anywhere. Still no problem.

That changes the production math entirely.

If production becomes cheaper to automate with robots in the home country than to outsource to Asia or Africa, places like the U.S., Germany, and the U.K. will see a huge return of manufacturing that was once sent abroad.

“Made locally” will become the standard again.

Obviously, workers won’t benefit from this, but consumers will. From much lower prices.

Workforce That Never Sleeps

Analysts predict that by the end of this decade, an advanced humanoid robot could cost under $50,000, less than a mid-range car.

Once purchased, it can operate continuously, needing only electricity and occasional maintenance. Nothing close to a human worker.

That’s a 24/7 workforce with no payroll, no breaks, and no burnout.

This would inevitably drive down the price of many goods, from electronics to groceries, because the labor component (often the biggest expense, even with cheap labor) would effectively vanish.

Robots could also eventually be used to build other robots, pushing costs of the robots itself lower still.

But there’s the second side to this story we all know.

Entire industries built on human labor will be disrupted. Warehouse workers, cleaners, delivery drivers, and service staff could see their roles replaced or reduced.

The transition will be uneven, with some countries adopting humanoid robotics faster than others, but the overall direction is clear.

Reality

Of course, there are still real challenges.

Safety remains a major concern. A humanoid robot strong enough to lift heavy objects is also strong enough to injure someone accidentally and heavily.

Questions about liability, regulation, and certification are far from resolved.

Laws are needed. Just like laws are now being introduced and adopted for AI.

There’s also the issue of reliability. Many demos shown by companies are still highly controlled. Some even rely on human-assisted remote control for training or demonstration purposes.

Mass adoption will require a level of consistency and trust that’s not fully proven yet.

But that hasn’t held back any of the major tech companies ever, has it?

And then there’s the fear of autonomous robots… cooking up a revolution themselves.

Five Years From Now

We probably won’t see humanoid robots walking freely through city streets next year, or in 5.

Because that’s not the intended use right now.

But within the next five years, it’s likely they’ll be common in factories, warehouses, hospitals, logistics centers, and even many homes.

Figure aims to produce 100,000 units by 2029. Tesla’s goal is ten times that. And smaller companies like Unitree in China are already offering simpler humanoids for around €16,000. Cheap.

Humanoid robots are no longer a futuristic concept.

They’re the new kind of industrial revolution. We can’t even imagine…